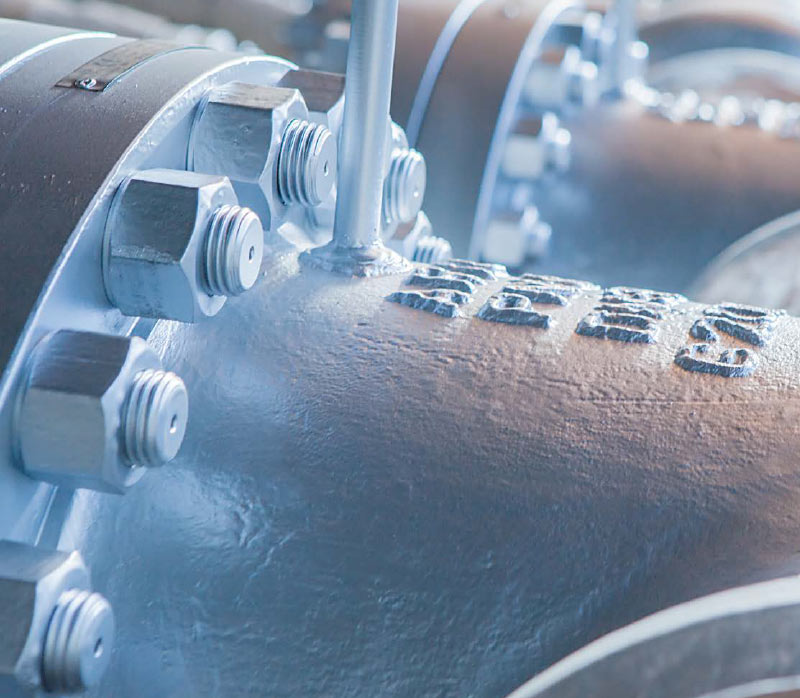

The Universal Pipe Coating (UPC) range is designed to help ensure maximum performance and deliver cost savings vs. traditional solutions. It provides long term corrosion protection for equipment operating at extreme temperatures, and is flexible to use in both insulated and non-insulated conditions. The complexity of coating specifications for process pipe can be a major contributor to project cost as well as increasing the likelihood of issues such as CUI. Typically, challenges such as pipe segregation, onsite rework and interchangeability during the construction phase, can lead to higher than expected costs and reduce productivity. The UPC approach presents an alternative to traditional coating specifications, tailored to reduce complexity and minimize cost from specification stage through to asset operation. Corrosion under insulation (CUI) is one of the most expensive challenges facing any asset owner and costs industry millions of dollars annually. Traditional CUI solutions can be costly, with specialist application characteristics that can increase risk of failure in service. UPC technology targets the key application drawbacks of traditional CUI solutions, significantly minimizing the risk of CUI and the cost of rework, whilst maximizing productivity.